Co-advisor: Prof. Mirela Ben-Chen

In recent years, 3D printing has gone through a democratization process and is becoming more popular with nonprofessional users. It is estimated that in 2021 alone, 2.2M 3D printers were globally sold. 3D printing, especially Fused Deposition Modeling (FDM), is a popular tool for hobbyists, makers, designers, and artists and can be found in personal households and communal FabLabs. This trend leads to the emergence of creative use cases and new workflows for interacting with 3D printers.

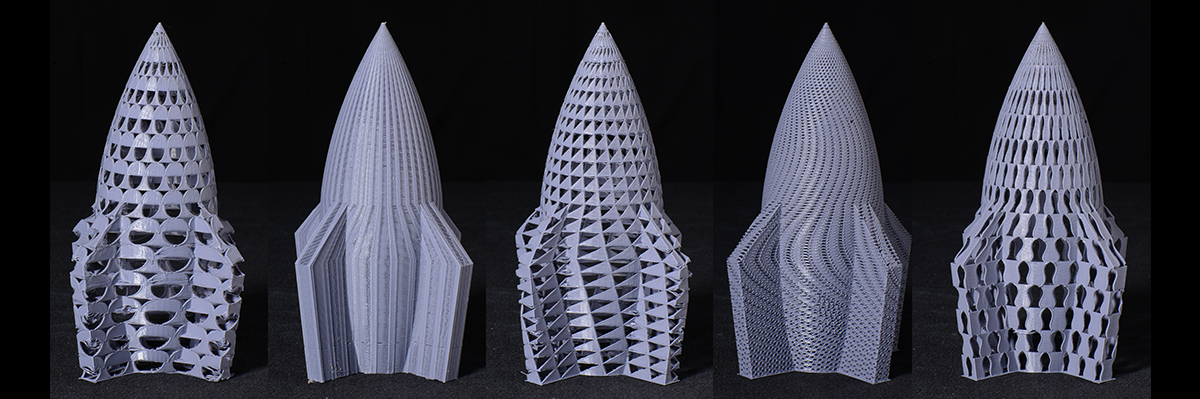

We are developing a set of design tools based on non-direct toolpaths. Non-direct toolpaths are printing paths that, when executed, result in a different geometry than planned due to the material behavior. Currently, using similar effects usually requires expertise both in programming and in operating 3D printers. Our design tool is aimed at being used by non-professional users. We are developing custom intuitive interfaces that allow local editing of a 3D model by adding textures onto the model’s surfaces.

We aim to enhance the creative user experience for non-expert users, allowing them to express their creativity and provide greater design freedom.